Troubleshooting

Your ion exchanger system is not running smoothly? Unusual discharge values, shortened loading cycles or increased pressure loss and the resin analysis shows that the resin is not responsible? Then we will find out the reason why your system is not running as desired.

Our decades of experience with ion exchange systems can save you a lot of time and money. Tell us about your problem and the conditions in your system. Often we are already able to identify possible causes and provide valuable information on how to solve the problem.

However, we are also happy to visit you on site to get a personal impression of the system. You will then receive a written report with clear recommendations for action. Take advantage of our extensive experience with ion exchange systems of all kinds instead of poking around in the dark for a long time.

If your system has not been running as desired for a long time or if you want to ensure optimal operation, we will be happy to take care of an inventory to enable a recalculation and optimisation of your existing system.

Please contact us by phone or by e-mail so that we can send you an individual offer.

Plant audit, review

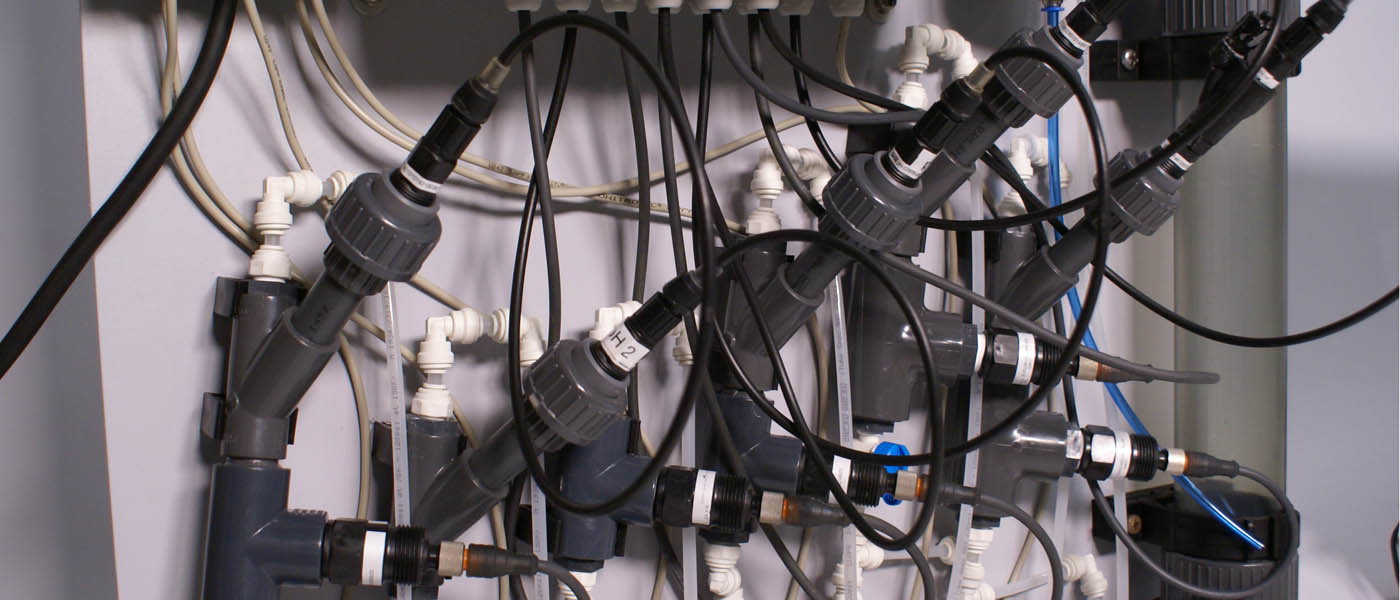

You would like to ensure the optimal operation of your ion exchanger system or your system is not running as desired? In order to enable a recalculation and optimisation of your system, we provide a review of the status quo. We would be happy to visit you on site to get a personal impression of the system.

We survey the structural details of your system and assess the current process. Based on our decades of experience, we identify existing structural improvement potential within a financially and environmentally worthwhile framework. It goes without saying that we take into account the latest developments on the process engineering market. In addition to independent recommendations, we are also happy to present our own new methods, for example, for self-optimisation of your DI system (Mi-Vision). To optimise your process, we check set flow rates and regrind settings and, if necessary, recommend resin analyses to estimate the remaining service life. Precise regenerant settings tailored to your achievable throughputs will save you money and chemicals. If you are (should be) considering a resin change, we can make independent recommendations on the most suitable resin for you. In order to find exactly the right resin, we are also happy to offer you trials in our technical centre (process development).

Furthermore, we give clear recommendations for well-structured process control. Because only a recipe adapted to the individual situation can lead to maximum efficiency for you and your process.

Do you want your plant and your process to show their best side as soon as possible? Then please contact us by phone or by e-mail so that we can arrange an appointment for an assessment and send you an individual offer.

Maintenance of our systems at your site

You want to make sure that your plant is always on its best behaviour? Take advantage of our decades of experience and let us help you with this challenge!

We offer you an offer for a maintenance contract that is individually tailored to your system and situation. Regular inspections of your system, including the replacement of wear parts, as well as the testing of your measurement technology, ensure the proper operation of your system. We also offer you advice by telephone and remote maintenance options to ensure that your system is always operating at its optimum.

And should something go wrong, we guarantee prompt assistance to get your process up and running again.

If you – like us – think that prevention is cheaper than standstill, please contact us by phone or by e-mail so that we can discuss your needs together and send you your individual offer.

This post is also available in: German